Re: 3.7L 180HP rebuild with pics!

Ok....how to install a new cam ...with engine in boat. Sorry forgot to get photos as I was doing it, but earlyer photos in this thread can be used if needed.

The intake and valve cover need removed. Once that is done remove the rockers and push rods, make sure they are kept in order, each rod and lifter must go back in the same spot it was removed from.

Rotate the engine until its at TDC and remove the harmonic balencer, stator, coolant pump cover, coolant pump, timining cover, lifter cover, fuel pump and all the lifter. With a new cam the lifters should also be changed since the lod ones are "married" to the old cam and will not function corectly with the new cam.

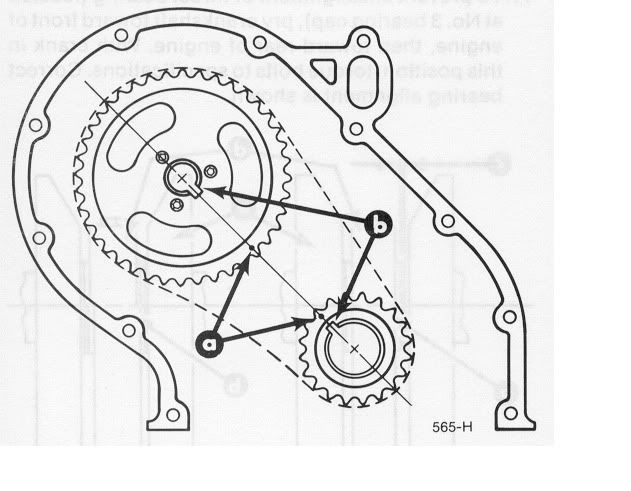

Once the timing chain is reached, the three bolts that hold the spocket to the cam need removed. Then pull both gears off at the same time, be careful the key in the cam is loose and may fall out, it should look like the photo when the engine is at TDC.

Once the sproket is removed, remove the race thet holds the cam in. It has two bolts that hold it to the block.

Now the cam can be removed, as long as the cam bores have not been machined, there are no bearings. The cam rides directly in the block. If the cam bores have been machined take extra caution not to knock the bearings out as the cam is pulled from the block.

After inspecting the bores to make sure there is no damage the new cam can be install.

Clean the cam with parts cleaner or carb cleaner.

Once the cam is clean, apply any kind of assembly lude that is formulated for Flat Tappet cams and lifter, to the #4 lifter lobes and the two lobes that ride in the block on eather side of the lifter lobes. I used a molly based lube that also has graphite in it, that way it sticks to the surface better and dosent run off before the cam is broke in.

Slide the cam into the block carefully, once the first two bearing lobes are in and are holding the cam in the block, apply lube to the next set of lobes. Then slide the cam in so that set of lobes are in the block. Continue this until the very last set of lobes is left to go in.

Once the cam is in so there is only one set of lobes left to slide in apply the lube to the lobes and the cam gear the drives the Distributor.

After the lube is applied, use one bolt to hold the sproket on the end. The sproket will be used to hold onto and slid the cam the rest of the way in untill it is fully seated.

Installing the cam this way will keep the mess down and the lube from covering your hands. Also since the only way the cam can be reached in the engine once installed is through the crank case the sproket will allow you to be able to guid the cam into the last seat in the rear of the engine.

.