Not sure where to post this question....

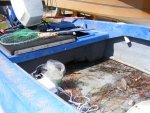

I recently bought another boat...project. Trihull, 15' with an outboard. It needs the usual--transom, deck and stringers. After removing the cap and some of the soaked foam Im seeing that altho there are 3 stringers ( 2 outboard --rotted wood and 1 keel which is 4" across and hollow.) the foam itself is structural. When there is no foam ( and at this point all the wood is gone from the outer stringers) there is no strength to the hull. It is 2 layers of roving.

The goal was to rebuild the hull with no wood --except for the transom and leave only the foam in the sides and stringers--not the bilge--maybe put in pieces of EPS from lowes so that the foam doesnt get soaked again.

Is it possible to retrofit ribs/bulkheads to reinforce the hull ( 8 lb foam encased in glass with pvc tubes to allow the water to drain) and leave the space between the stringers and bulkheads free to drain?

I recently bought another boat...project. Trihull, 15' with an outboard. It needs the usual--transom, deck and stringers. After removing the cap and some of the soaked foam Im seeing that altho there are 3 stringers ( 2 outboard --rotted wood and 1 keel which is 4" across and hollow.) the foam itself is structural. When there is no foam ( and at this point all the wood is gone from the outer stringers) there is no strength to the hull. It is 2 layers of roving.

The goal was to rebuild the hull with no wood --except for the transom and leave only the foam in the sides and stringers--not the bilge--maybe put in pieces of EPS from lowes so that the foam doesnt get soaked again.

Is it possible to retrofit ribs/bulkheads to reinforce the hull ( 8 lb foam encased in glass with pvc tubes to allow the water to drain) and leave the space between the stringers and bulkheads free to drain?