lakeorbay

Petty Officer 2nd Class

- Joined

- Apr 15, 2009

- Messages

- 180

Re: Would you patch this or this?

Re: Would you patch this or this?

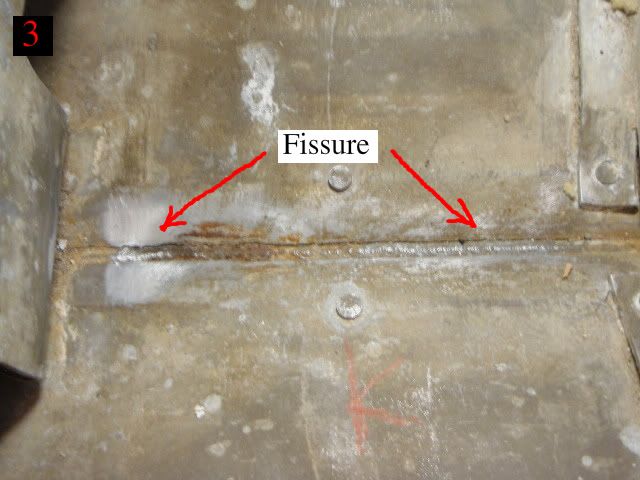

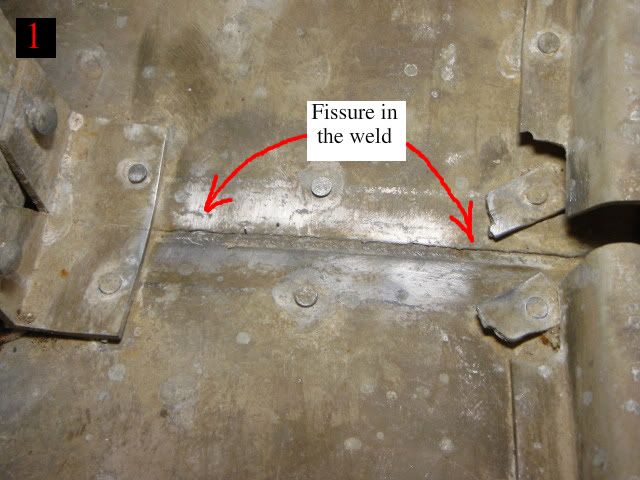

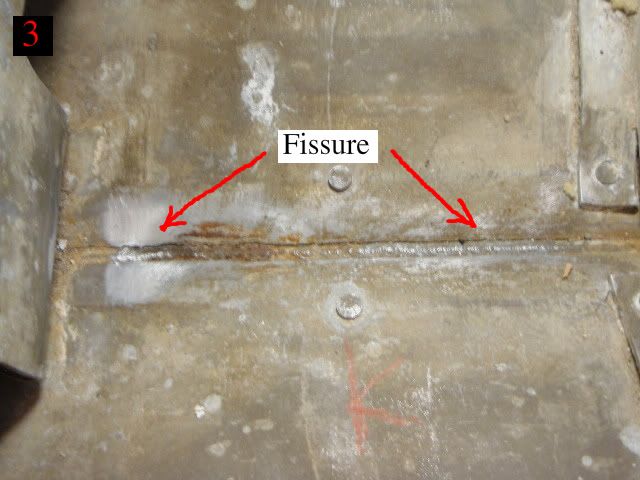

Okay, here's the leak.

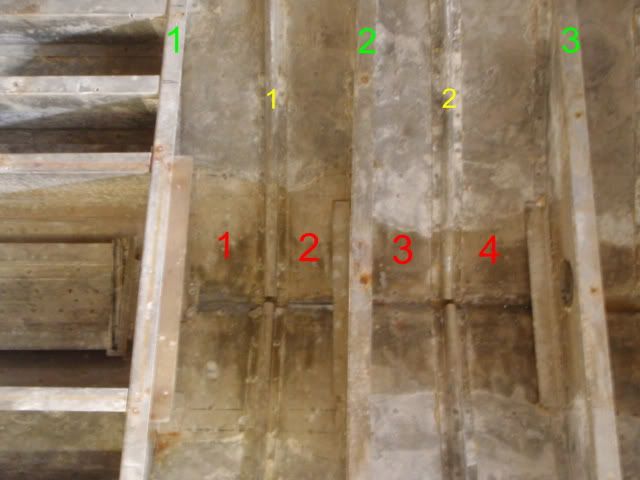

Here's an overview. The pics following will have corresponding numbers with this one.

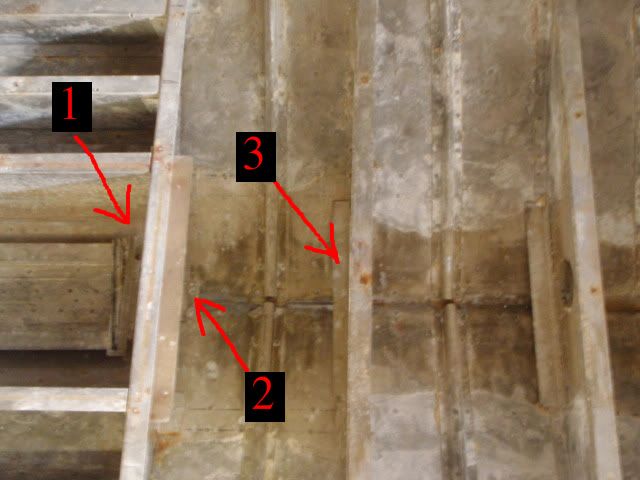

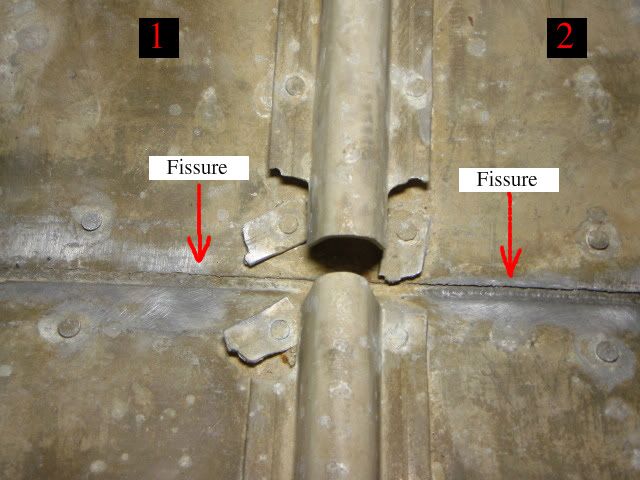

Those dark lines are not shadows caused by the light. Those are actual separations in the weld.

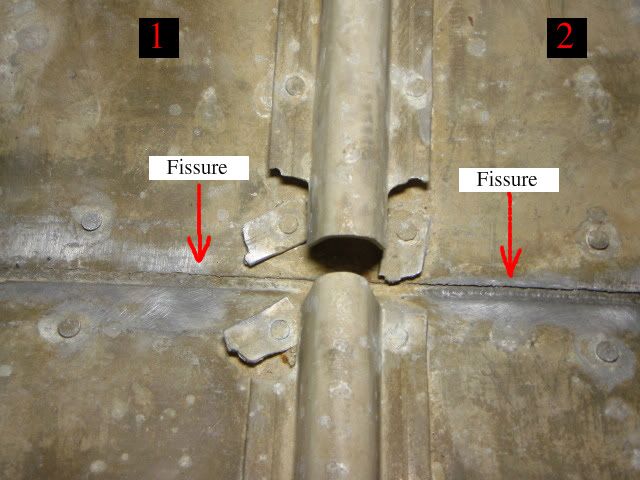

.....again

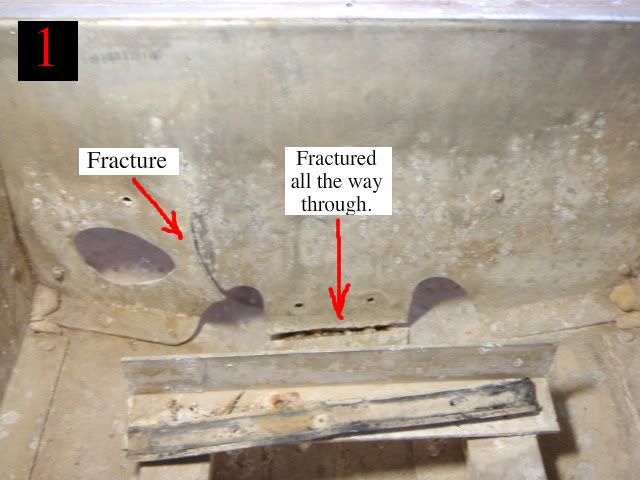

No graphic needed here. You can't help but see that one.

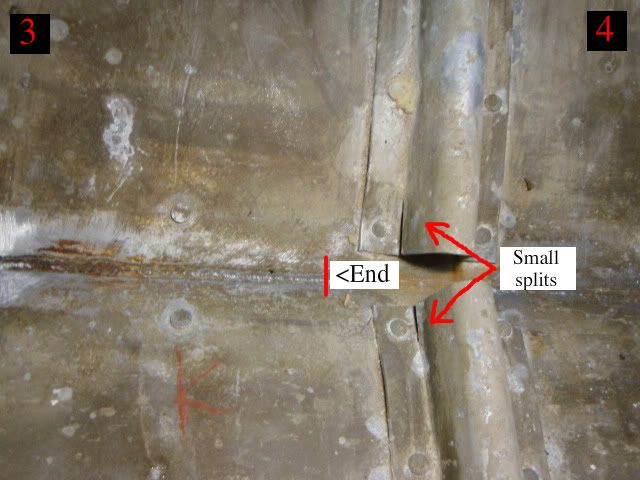

.....starting to taper off a bit (so it seems). No pun intended.

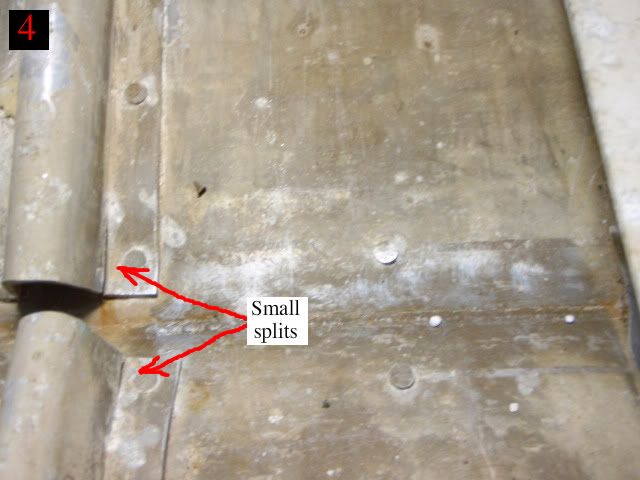

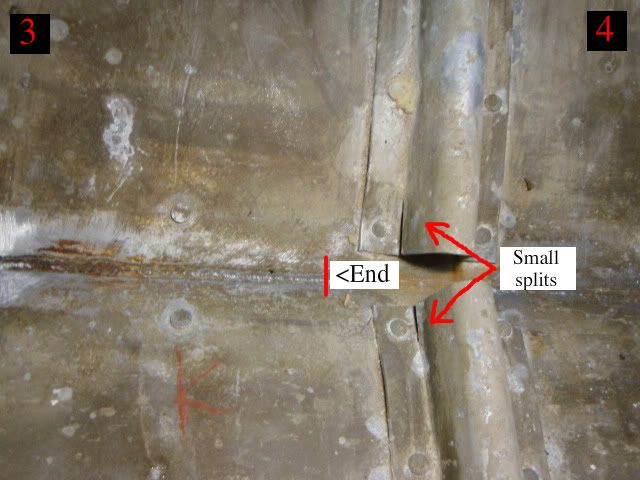

This appears to be the end of the fissure and a couple splits in what I call ribs.

to be cont.....

Re: Would you patch this or this?

Okay, here's the leak.

Here's an overview. The pics following will have corresponding numbers with this one.

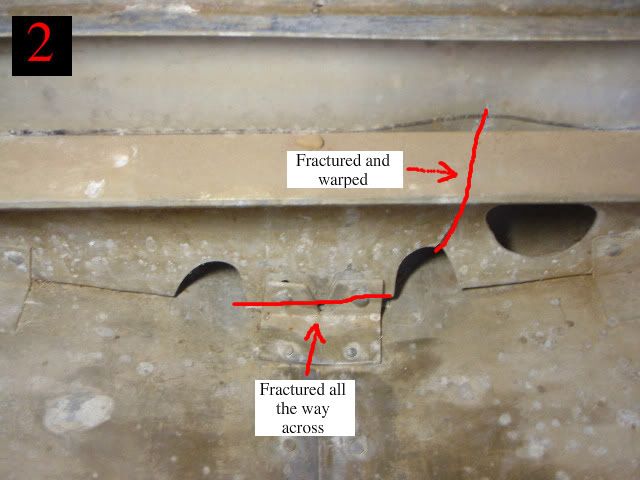

Those dark lines are not shadows caused by the light. Those are actual separations in the weld.

.....again

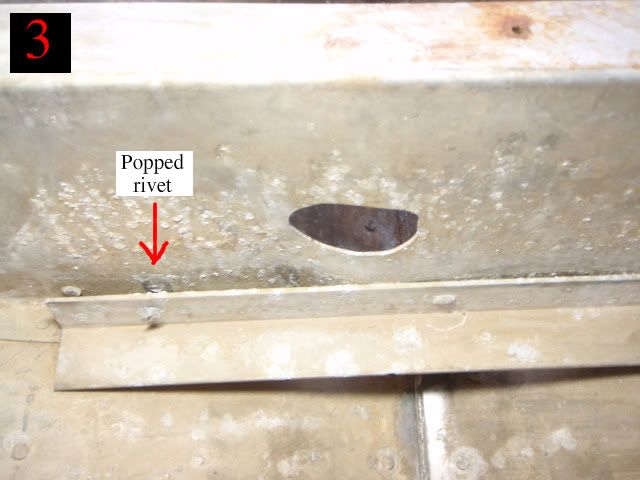

No graphic needed here. You can't help but see that one.

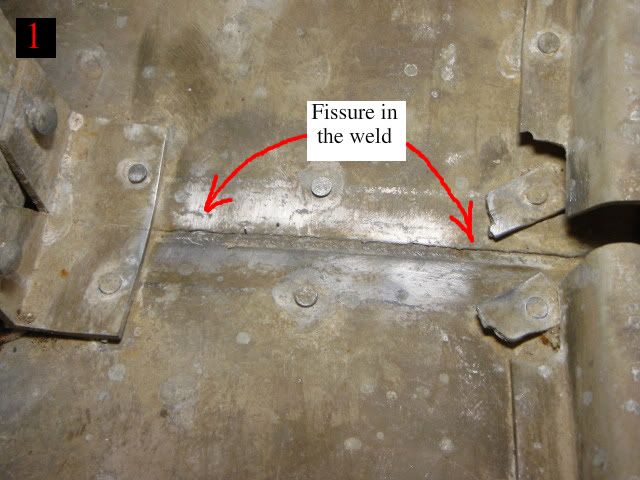

.....starting to taper off a bit (so it seems). No pun intended.

This appears to be the end of the fissure and a couple splits in what I call ribs.

to be cont.....