Re: The inevitable 1973 15? Reinell tri-hull restoration!

Re: The inevitable 1973 15? Reinell tri-hull restoration!

The brass should work just as well as stainless I would think.

The triple digit temps......well, some of my restore went on through winter, and I had the garage pretty warm

The warmer the temp, the faster it sets up and the shorter the time to work with it. It'll definitely still set up.

The deck....I would recommend putting the cap on, making sure the hull measures out perfectly, and then doing the deck. If you do the deck first, and things are even slightly out of place....you'll have a hell of a time getting the cap to fit. I used 3/4" ACX on my deck, and what worked best in the bow was cutting a large piece of cardboard to the exact size I needed.....easy to do with a box knife in the boat.....then using that as a pattern. It still took 3 or 4 'test fits' to get it perfect. I tapered the front/bow piece where it meets the hull as well, so go slightly oversize on your pattern up in the hull if you want to allow for a taper.

I've been wanting to improve on things......put the front seats in the bow on hinges, and add a couple storage compartments. Maybe an 'anchor box' under the front. Very minor updates to consider after you've done everything else!

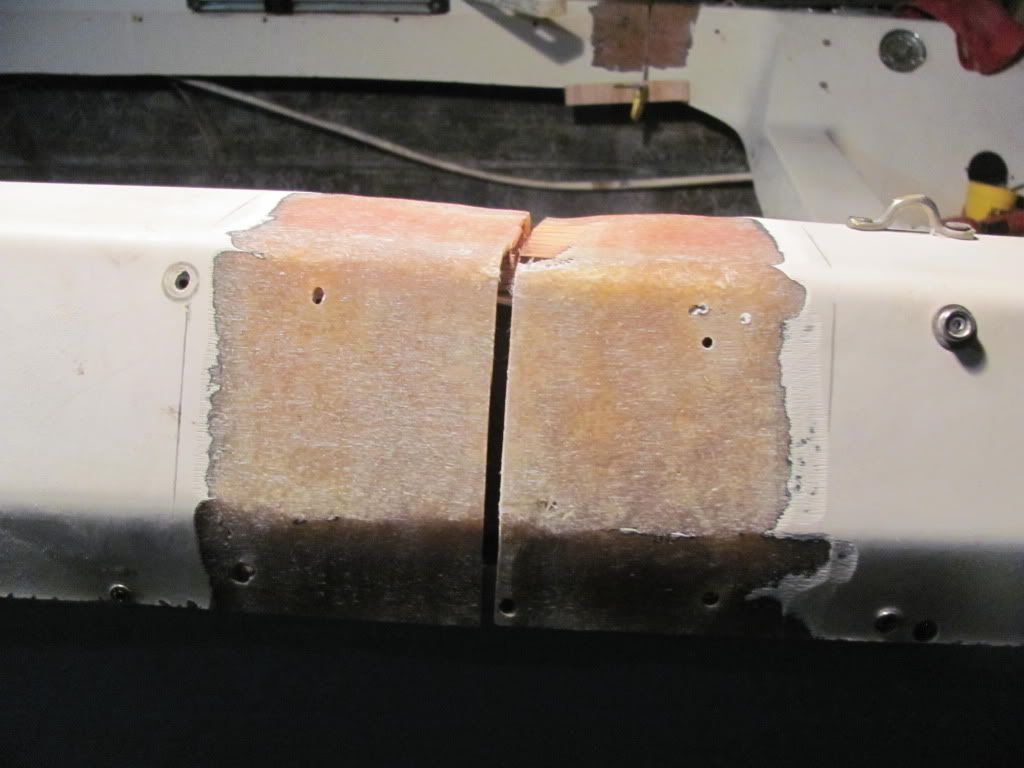

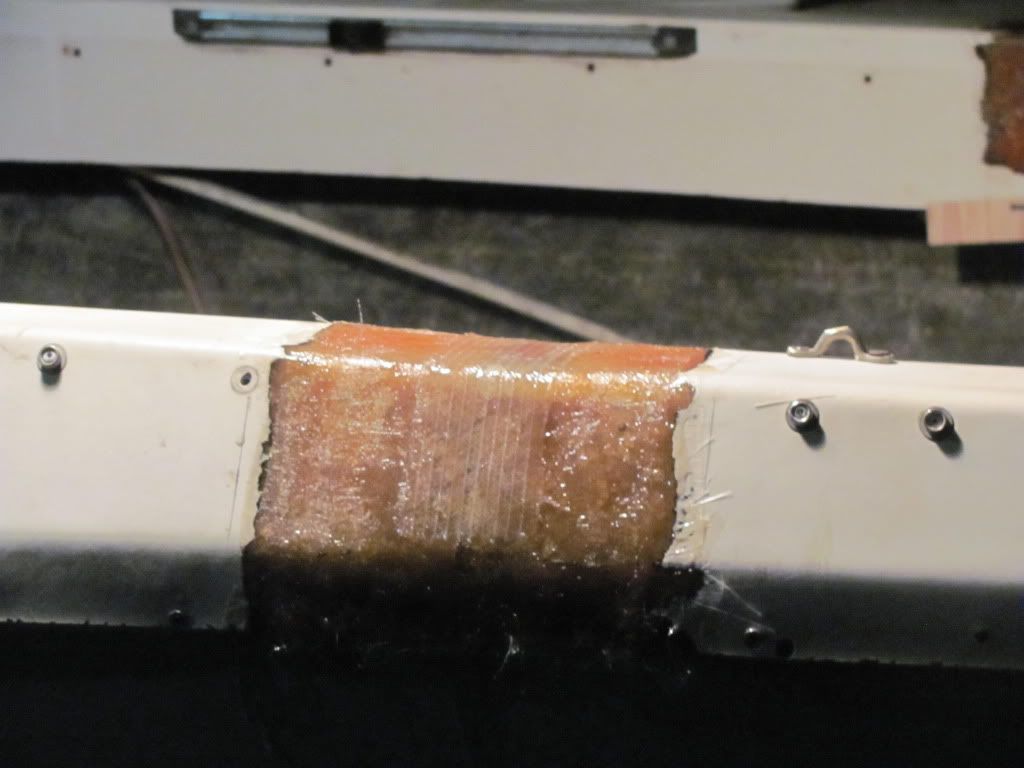

I think the easiest part was after the deck was on, i.e.: Prepping the deck topside, the tabbing, etc. Nice flat surface, and you get to sit down for a lot of it

I felt so good about how well it turne dout, I hated to cover it with carpet

Home Depot still carries marine carpet by the way. Not the high end real plush stuff, but just fine for a family/fishing/whatever boat.