Re: Staring at this vessel in my yard... Is she worth fixing?

Re: Staring at this vessel in my yard... Is she worth fixing?

greenbush future is 100% correct...

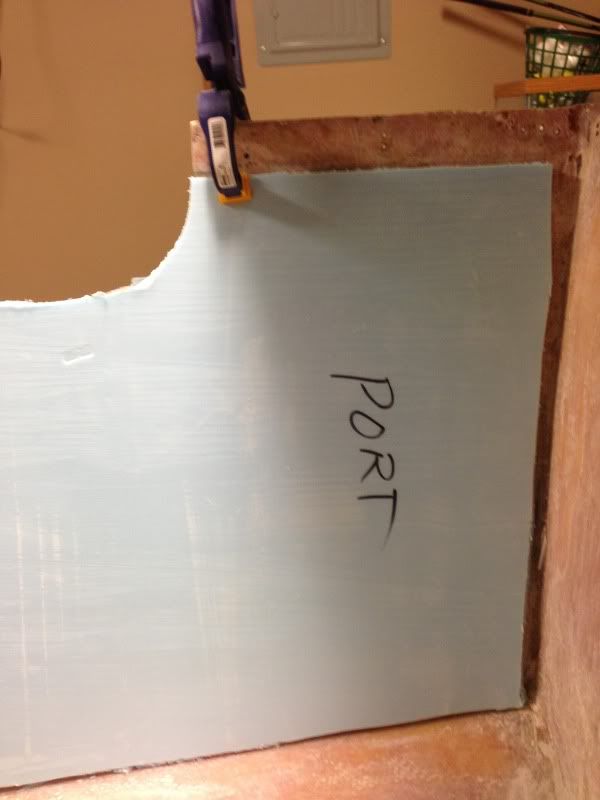

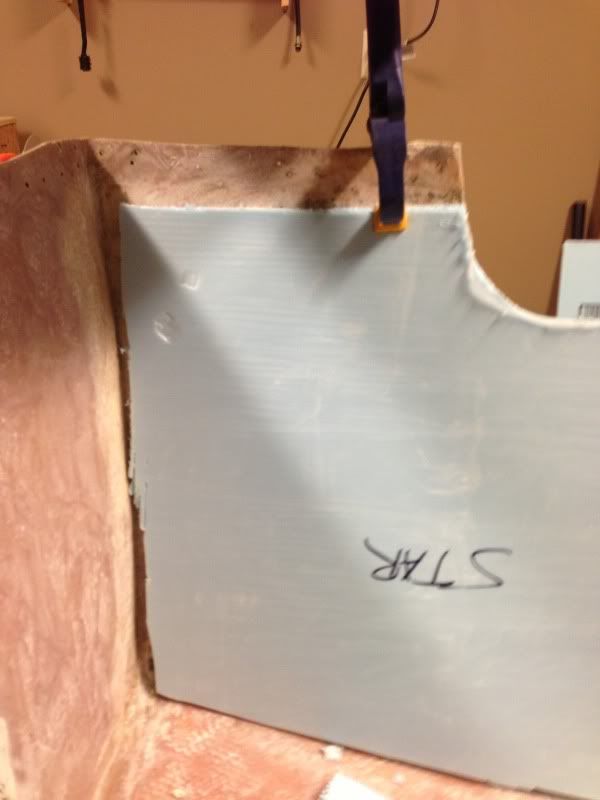

It is not necessary to do any tabbing there...as a matter of fact, try and leave that space clean and clear for the attachment of a "nailer" that will eventually go all the way around that inside rim...that is what will give the rub rail a solid purchase on the screws that hold it in place...it can be a strip of plywood, coated in resin and CSM, attached with some PB and a little CSM if you'd like, approximately 3/4" X 1"to1-1/2" ...when the cap goes back on, and you are ready to attach the rub rail back on, pre-drill the holes for the screws, smear some 5200 on the screws and run them home through the rub rail...

Definitely get some Acetone...you will use it over and over to clean your chip brush and bubble roller after each use to keep from ruining them, you will also be using it to wipe down everything that is about to get glassed, and cleaning up in general...if you don't already have, get a box of disposable latex gloves, when you are ready to do some glassing, put on two or three pairs, as they get gummed up and hairy, you can rip off a layer and keep going... and talcum powder...not only is it good to keep the itch down, you can use it when things get too sticky...like on your gloves or your chip brushes after you clean them out with Acetone...