Re: Bayliner Capri unintentional restoration project

When all this had dried I mounted it to the cap at the bow of the boat. I had some ss right angle/L-shaped brackets left over from the trailer resto so I used these to mount it using ss bolts countersunk into the wood so it can be filled over afterwards. Through cap fixings were sealed with sikaflex.

And so you can see what I mean about using the anchor compartment through the hole in the bow section or through the bow seat locker:

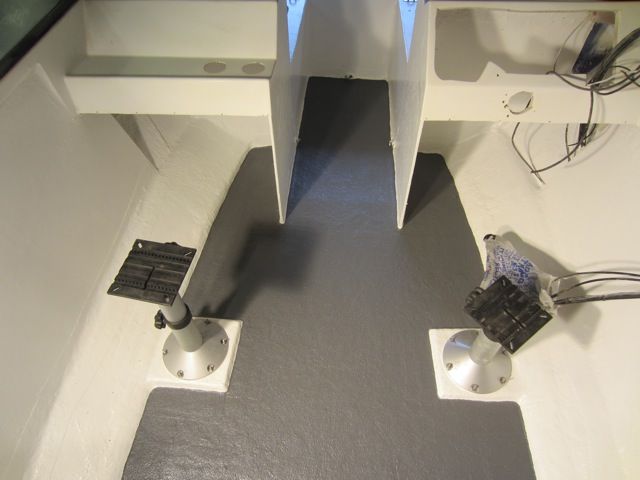

The top will obviously get filled with fairing filler to make a smooth transition to the cap and cover the metal brackets. Everything will get gelcoated including the cup holders. I started gelcoating today with the bilge; 1 coat of non-waxed gelcoat and 1 coat of waxed. I'm going to build a section around the exposed fuel tank so water drains around it rather than into it to get to the bilge. The top of this will be covered with holes for the hoses to come through, which will then get sealant around them so hopefully no water will get into the fuel tank area.

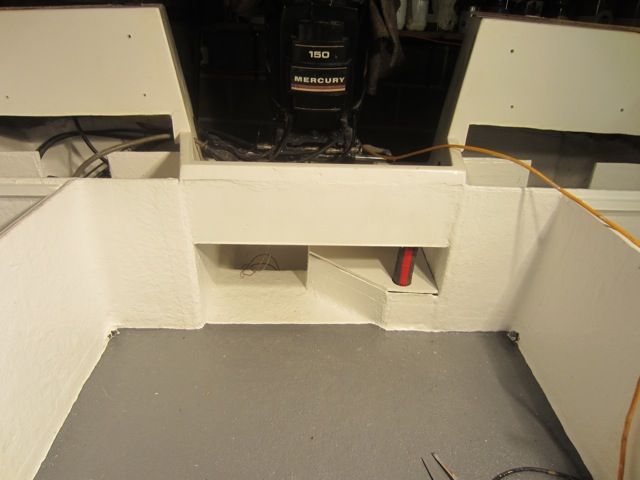

Pretty cold here still so the heater is in place to make it cure properly and it's covering up the exposed fuel tank on the port side just in front of the bilge.

When all this had dried I mounted it to the cap at the bow of the boat. I had some ss right angle/L-shaped brackets left over from the trailer resto so I used these to mount it using ss bolts countersunk into the wood so it can be filled over afterwards. Through cap fixings were sealed with sikaflex.

And so you can see what I mean about using the anchor compartment through the hole in the bow section or through the bow seat locker:

The top will obviously get filled with fairing filler to make a smooth transition to the cap and cover the metal brackets. Everything will get gelcoated including the cup holders. I started gelcoating today with the bilge; 1 coat of non-waxed gelcoat and 1 coat of waxed. I'm going to build a section around the exposed fuel tank so water drains around it rather than into it to get to the bilge. The top of this will be covered with holes for the hoses to come through, which will then get sealant around them so hopefully no water will get into the fuel tank area.

Pretty cold here still so the heater is in place to make it cure properly and it's covering up the exposed fuel tank on the port side just in front of the bilge.