Woodonglass

Supreme Mariner

- Joined

- Dec 29, 2009

- Messages

- 25,932

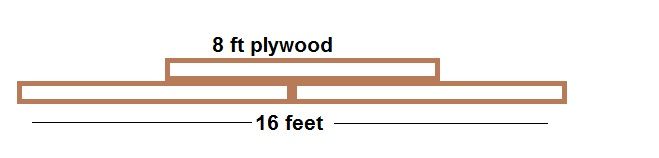

You can do scarf joints but...there are two good alternatives. Lap Joints and Sister Joints. If your stringers are going to be 3/4" thick then use 3/8" plywood and lap them at the 48" mark and you can make em as long as you need. This drawing illustrates How to make a 16' stringer using lap joints.

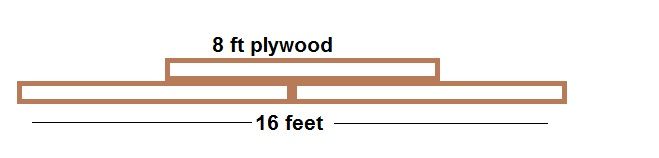

This drawing illustrates how to use a "Sister Joint" But the two ends of 3/4" plywwood together and then use 1/4" plywood on either side to glue and screw the "Sister" pieces on. A 36" long "Sister" 18" on either side of the joint and use Titebond III wood glue and deckscrews will yield a strong joint with NO FLEX.

Scarfs are Hard to get Perfect and even harder to glue up and keep aligned properly. Really not needed for stringers. The above mentioned methods are proven and more than acceptable to use.

This drawing illustrates how to use a "Sister Joint" But the two ends of 3/4" plywwood together and then use 1/4" plywood on either side to glue and screw the "Sister" pieces on. A 36" long "Sister" 18" on either side of the joint and use Titebond III wood glue and deckscrews will yield a strong joint with NO FLEX.

Scarfs are Hard to get Perfect and even harder to glue up and keep aligned properly. Really not needed for stringers. The above mentioned methods are proven and more than acceptable to use.