Scaaty

Vice Admiral

- Joined

- May 31, 2004

- Messages

- 5,180

Re: Inboard outboard air cooled engine

NO-NO-NO...think what I said.

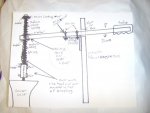

The threaded rod!..it will move a small amount SIDE TO SIDE..with the side nuts..also threaded..MINIMAL.

The shift lever goes up and down!

Go back and look again...then " visualize "...what I'm saying..

Maybe I'm wrong, But I thought the shift rod in L U pulled up and pushed down. Instead of twisting.

NO-NO-NO...think what I said.

The threaded rod!..it will move a small amount SIDE TO SIDE..with the side nuts..also threaded..MINIMAL.

The shift lever goes up and down!

Go back and look again...then " visualize "...what I'm saying..